The 9-5/8" Oilfield Cementing Accessories Ltc Top Drive Cement Head

The Oilfield Cementing Accessories Ltc Top Drive Cement Head is a high-quality tool designed for efficient and effective cementing operations in oilfields. Ideal for use in applications requiring precision and durability, this head tool ensures optimal performance and reliability. Crafted with advanced materials and engineering, it supports seamless integration with top drive systems, meeting industry standards.

- Brand: Sunjoy

- SKU: 358

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

The 9-5/8" Oilfield Cementing Accessories Ltc Top Drive Cement Head

Products Information

---------------------------------------------

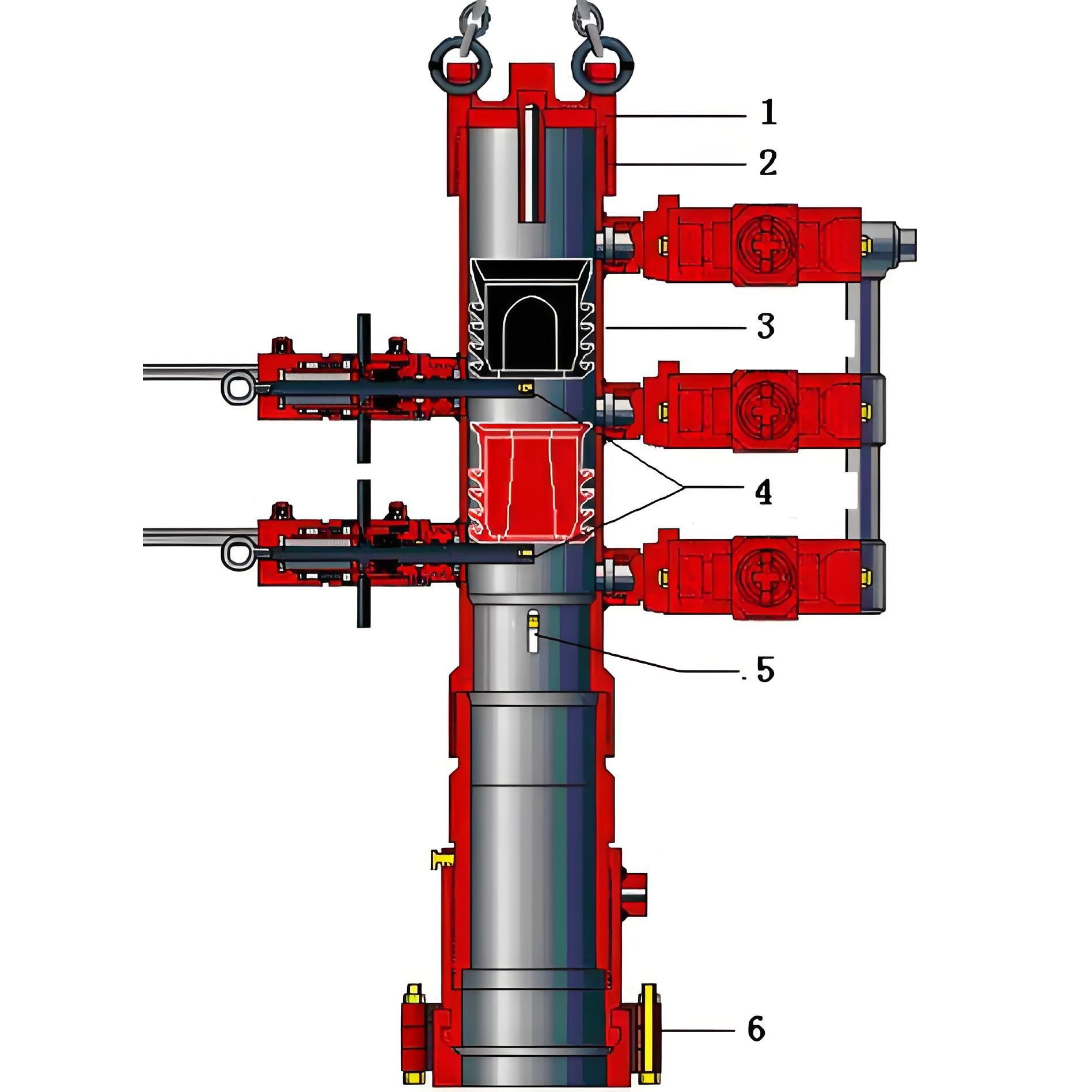

The cement head is a crucial equipment in well cementing operations, connecting casing with surface manifolds. It is used to perform core operations such as circulating well flushing, injecting spacer fluid, injecting cement slurry, releasing rubber plugs, and displacing slurry. Its main body is made of AISI4145H alloy steel, with a working pressure up to 35MPa, and it is compatible with various casing specifications ranging from 20 inches to 2-7/8 inches.

Core functions and structural components: Sealing and pressure control: Precise switching of high-pressure fluid channels is achieved through built-in plug valves, balance tubes, and quick-release connectors, ensuring no leakage during cement injection.

Rubber stopper storage and release: The built-in rubber stopper storage, combined with a stopper or motor drive mechanism, enables remote, contactless release of rubber stoppers, avoiding the risk of displacement caused by pressure fluctuations in traditional mechanical stoppers.

Compatibility design: The quick-release connector conforms to API standard threads, allowing for quick docking with various ground pumping equipment, thereby enhancing operational efficiency.

Type | Plug qty | need to stop the pump and install plug | work situations | Work pressure | Typical application fields |

Single plug cement head | 1 Top/down | Yes | Simple Shallow Cementing | ≤30MPa | Shallow well, low-pressure well |

Double Plug Stoppers Cement head | 2 Top+down | No | Conventional dual Plug cementing, continuous two-stage cement injection | 30–35MPa | Deep wells, ultra-deep wells, shale gas wells |

Top drive cement head | 2 | No | Casing rotation cementing | ≥35MPa | High-temperature and high-pressure directional wells, horizontal wells |

Ultra-high pressure dual plug cement head | 2 | No | Ultra-deep wells, ultra-high pressure gas wells | >35MPa | Deep-sea cementing, supercritical CO₂ storage wells |

Note: Dual plug cement heads have become the mainstream choice for modern cementing operations because they can complete plug deployment without stopping the pump, significantly improving mud displacement efficiency.