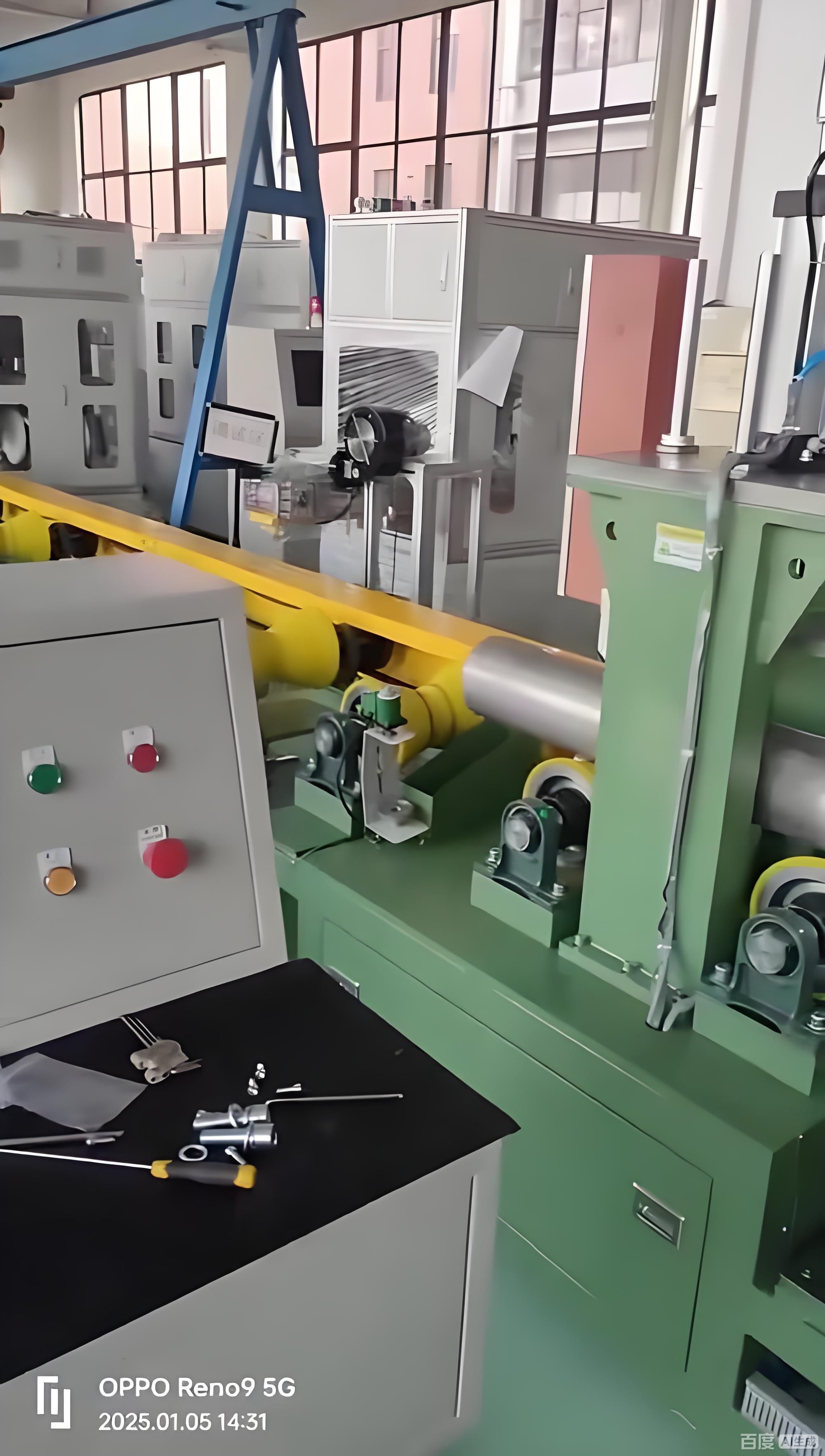

Seamless steel pipe online eddy current flaw detector Production Line

The "Seamless Steel Pipe Online Eddy Current Flaw Detector" from HENAN SUNJOY OIL MACHINE AND MATERIAL CO., LTD ensures precise and efficient flaw detection in pipeline materials. Ideal for professionals, it guarantees top-notch quality assurance.

- Brand: Sunjoy

- SKU: 5

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

Seamless steel pipe online eddy current flaw detector Production Line

Product Overview

The Sunjoy BW-100P Eddy Current Testing Instrument is primarily used for detecting defects in metal pipes, rods, wires, filaments, and profiles, such as surface cracks, dark seams, slag inclusion, and open cracks, with high detection sensitivity.

The instrument operates by passing an alternating current of a certain frequency through the detection coil. When the test specimen approaches the coil, its geometric dimensions, electrical conductivity, magnetic permeability, and metallurgical and mechanical defects will cause impedance changes in the coil. The instrument detects the changes in the coil’s impedance, amplifies and converts the resulting electrical signal, and drives the alarm or display device, ultimately identifying defective samples.

It features a Windows-based Chinese operating interface and modular operation, offering X-t, Y-t, and V-t real-time display modes for the user to choose from.

The instrument automatically records and displays defect locations.

The eddy current testing signals can be replayed, analyzed, stored, and printed.

It automatically generates inspection reports that include defect numbers, defect locations, specifications, shifts, dates, inspectors, and test parameters.

The full digital design technology ensures that no recalibration is needed when changing product specifications, providing easy-to-use, user-friendly operation.

Function and Applications

The eddy current testing instrument is commonly used in military, aerospace, railway, and industrial enterprises in outdoor or field settings. It is multifunctional, highly practical, and offers excellent performance-to-cost ratio. Drawing on years of experience in manufacturing eddy current testing instruments, it meets the needs of various users. The instrument can be widely applied to online or offline defect testing of non-ferrous metals, ferrous metal pipes, rods, wires, filaments, and profiles. It has high sensitivity in detecting defects such as surface cracks, dark seams, slag inclusion, and open cracks.

Featuring a Windows-based Chinese operating interface and modular operation, the instrument offers various display modes for selection. It also uses full digital design technology, ensuring easy operation without the need for recalibration when changing product specifications.

Working Principle

The instrument passes an alternating current of a certain frequency through the detection coil. When the test specimen comes close to the coil, its geometry, conductivity, magnetic permeability, and metallurgical or mechanical defects cause impedance changes in the coil. The instrument detects the changes in impedance, amplifies and converts the resulting electrical signal, and activates the alarm or display device, detecting defective samples.

Operating Conditions

Ambient temperature: -20℃ to +40℃

Detection speed: 0.1 meters/min to 500 meters/min

Frequency range: 100 Hz to 1 MHz

Gain: 0 to 60 dB, adjustable in 1 dB steps

Bandpass filtering or speed matching

Full digital computer parameter adjustment

Real-time impedance plane display

X-t, Y-t, and V-t real-time display modes for selection

Automatic defect location recording and display

Dynamic fixed-length marking function (not required for high-speed testing)

Head and tail signal removal function

High-precision real-time and delayed alarm outputs

Multi-phase/amplitude alarm technology

Automatic date and time display

Eddy current signal playback, analysis, storage, and printing functionality

Windows interface with modular human-machine interaction

Power supply: 180V to 240V, 50Hz

Ambient temperature: -20℃ to +40℃

Technical Parameters

Sensitivity to small cracks and other defects

Fast detection speed and high sensitivity for surface and near-surface defects

Instantaneous inspection results

Good equipment compatibility

Minimal preparation required

No physical contact required between the probe and the object under inspection

Capable of inspecting conductors with complex shapes and dimensions

After-Sales Service

Dear customer,

We guarantee the authenticity and quality of our products, and we also provide free delivery. If you're unfamiliar with how to use our products, we offer training to ensure you can operate them effectively. Once a product is sold, we provide top-tier after-sales service. For more details, please feel free to contact us and inquire about product availability.

Repair Instructions:

Thank you for choosing Henan Sunjoy Oil Machine And Material Co., Ltd. for your non-destructive testing equipment, testing instruments, and services. To better protect your investment, we have outlined the following service instructions:

We strive for absolute customer satisfaction through relentless effort.

We provide high-quality, professional services while saving costs.

We simplify warranty procedures to shorten maintenance time for your equipment.

Our products undergo strict testing by our quality department and are covered by appropriate warranty periods.

Warranty and Service Standards:

Our professional repair staff are trained to fully meet your service requirements.

Our inspection equipment meets national standards.

Our calibration certification meets the national level one metrology standards or the highest international standards.

Equipment Protection and User Rights:

Free warranty service for 2 years for non-destructive testing equipment and 1 year for other equipment.

Post-warranty services are available for repair.

Repair time, when spare parts are available, will not exceed 5 working days (excluding shipping time), with a response time within 2 hours.

Warranty Conditions:All warranty services are valid from the shipping date.

Shipping costs during the warranty period are covered by us.

The warranty does not cover:

A. Consumable parts like cables, fuses, and probes.

B. Damage caused by improper handling, non-compliance with procedures, or force majeure events (e.g., earthquakes).

C. Damage from self-dismantling under non-normal conditions.

D. Equipment without a valid warranty serial number.

Post-Warranty Services:

Three-month warranty for repaired parts starting from the shipping date.

Post-repair calibration services are available at the user's cost.

Our goal is to advocate for testing and measurement technology, provide advanced scientific equipment and technology, and help you improve work efficiency and comfort through sincere service. We aim to meet your needs and welcome your valuable feedback.

Upon completion of the transaction, you will receive a warranty contract detailing our services. Thank you again for your purchase!

Repair Process

Repair Cycle: For instruments sent for repair, we will arrange an engineer to inspect your equipment within one working day of receipt, and provide a quote. Upon confirmation of the quote by the customer, repairs will begin. Standard repairs are typically completed within 5 working days, though delays may occur due to imported material delays or unexpected issues.

Notice:

For out-of-warranty or external repairs, shipping and insurance costs are not included in the repair quote. These fees will be borne by the customer.

If sending equipment through a third party, ensure the instrument is protected from moisture, vibration, and shock during transportation. The packaging should be sealed with a plastic bag to prevent dust and particles from entering, and the internal packaging should be sufficient to prevent damage during transit.