S320-305-120 Oil Pumping Unit Information and Parameters

the S320-305-120 has advantages in high-torque, medium-stroke working conditions, suitable for: Deep wells (>1000m); High-viscosity crude oil (heavy oil); Secondary development after casing-damaged well sidetracking. This equipment is an ideal choice for old well potential tapping and energy-saving transformation, aligning with the national "dual carbon" policy for oilfield energy reduction and efficiency enhancement.

- Brand: Henan Sunjoy

- SKU: 25

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

S320-305-120 Oil Pumping Unit Information and Parameters

Core Conclusion: Model Authenticity and Manufacturer Confirmation

The S320-305-120 is a beam pumping unit (commonly known as a "nodding donkey") widely used in China's oil fields. Its naming follows the industry's internal coding logic: S + Reducer Rated Torque (kN·m) + Maximum Load at the Saddle Point (kN) + Maximum Stroke (cm).

Key Parameter Summary (Based on Manufacturer Technical Documents and Industry Standards)

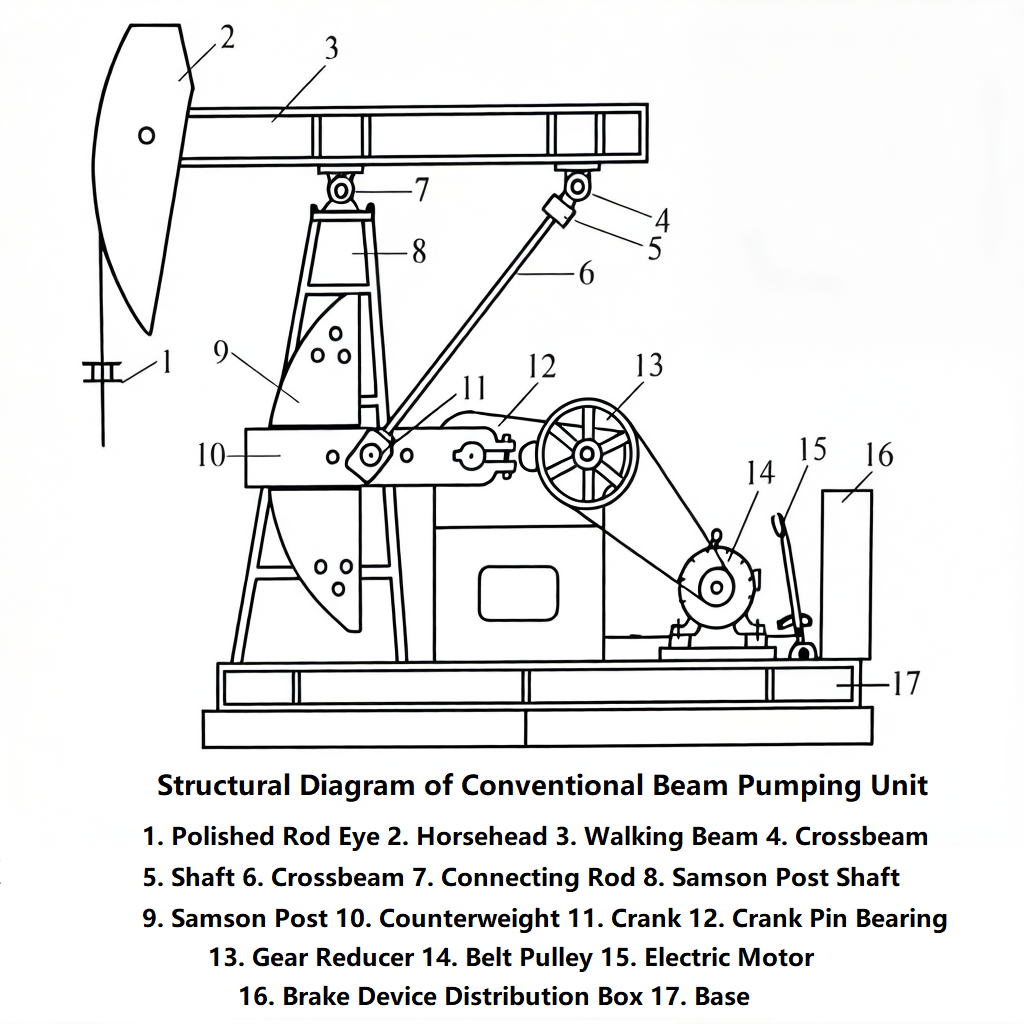

Structure and Working Principle

The S320-305-120 is a typical beam pumping unit, consisting of five core systems:

- Power System: A three-phase asynchronous motor (45kW) drives the reducer via a coupling to achieve high-torque, low-speed output.

- Transmission System: The reducer (reduction ratio ~20:1) outputs shaft rotation, driving the crank via a connecting rod to make the beam swing up and down.

- Execution System: The horsehead at the beam's front end connects directly to the sucker rod, achieving vertical reciprocating motion to drive the downhole pump plunger.

- Balancing System: The composite balance (crank counterweights + beam tail counterweights) reduces motor power fluctuations by over 30%, significantly enhancing energy efficiency and equipment life.

- Support System: A reinforced concrete foundation or steel structure base ensures the unit's stability under long-term vibration.

Application Scenarios and Regional Adaptability (Henan Puyang)

- In the Zhongyuan Oil Field core area (Puyang), this model is widely deployed for high-water-cut, low-yield oil wells.

- Compared to the CYJ series, the S320-305-120 has advantages in high-torque, medium-stroke working conditions, suitable for:

- Deep wells (>1000m);

- High-viscosity crude oil (heavy oil);

- Secondary development after casing-damaged well sidetracking.

- This equipment is an ideal choice for old well potential tapping and energy-saving transformation, aligning with the national "dual carbon" policy for oilfield energy reduction and efficiency enhancement.