Flush-By Unit

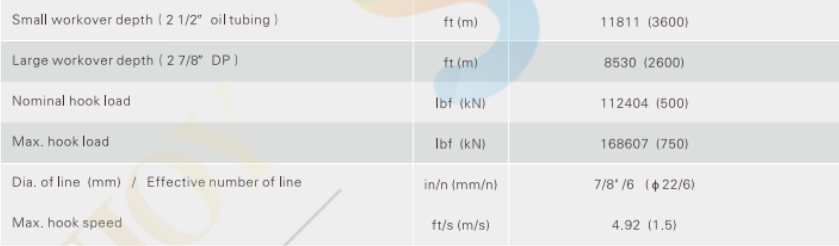

The rig is dual-use equipment with workover and flushing operation. Adopt 8x4 self-propelled carrier, deck-mounted diesel engine matches with hydraulic transmission case, the power is transferred to front and rear drive axle of carrier, drawworks, transfer case and pump assembly. The transmission case connects with hydraulic pump to supply hydraulic power for the equipments on the rig.

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

Core Concept:

A Flush-By Unit is a specialized component used in hydraulic or lubrication systems. Its primary purpose is to allow for the maintenance, replacement, or flushing of filters, heat exchangers, or other critical components without interrupting the operation of the main system.

How It Works:

The unit typically consists of a valve manifold (or multiple valves) that creates a bypass line parallel to the main equipment (e.g., a filter).

Normal Operation Mode: Fluid (such as oil or hydraulic fluid) flows through the main equipment (e.g., through a filter for purification or a heat exchanger for cooling).

Maintenance/Flush Mode: When the main equipment needs to be isolated, valves are operated. The fluid is diverted through the bypass line, going around the main equipment. This allows the main equipment to be safely removed, replaced, or back-flushed while the rest of the system continues to operate.

Key Advantages:

Increased System Availability: Eliminates the need to shut down the entire system for filter changes or service, significantly reducing downtime.

Enhanced Safety: Enables maintenance on equipment under zero-pressure or safe conditions, reducing occupational hazards.

Ease of Maintenance: Simplifies the process of filter replacement and system flushing.

System Protection: The bypass function prevents potential damage to pumps and prime movers that could occur from a blocked or interrupted oil line during maintenance.

Typical Applications:

Hydraulic systems in large industrial machinery

Lube oil systems in power generation (e.g., gas turbines, steam turbines)

Marine propulsion lubrication systems

Any critical fluid system requiring high uptime and online maintenance capability.