Bucking units

Bucking units are critical pieces of equipment in the oil and gas industry, designed to make or break threaded connections on tubular goods and downhole tools. These machines, capable of delivering high torque with precision, are essential for maintaining the integrity of connections in oilfield operations. As the demand for more complex and deeper drilling increases, the role of bucking units has grown in importance. This article explores the various types of bucking units—specifically rotational bucking units and continuous bucking units—their specifications, features, and applications, as well as insights into leading manufacturers like Galip.

- Brand: Sunjoy

- SKU: 25

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

1.General overview:

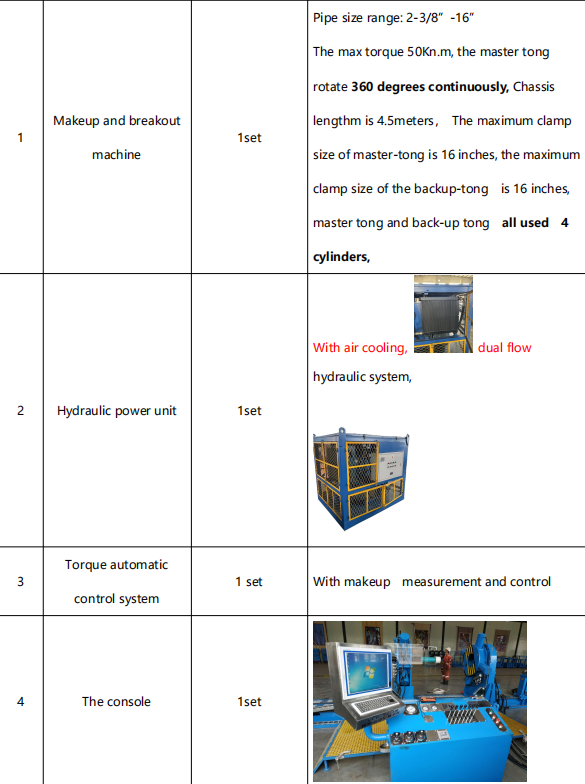

The master and backup tongs of this bucking unit are of cylinder clamping structure, and the

master tong rotate 360 degrees continuously, the diameter of clamping pipe can be continuously

changed, clamping different pipe diameters without changing the tong head, improving

production efficiency and safety, reducing labor intensity, and have been widely used in the

connection of petroleum tools

2.The torque controller can set the make-up torque, automatically control (torque overload

protection), and automatically generate turns - torque, time - torque, speed - turns. The torque

query database can be set to input material, pound grade, specification connection type, maximum

torque, minimum torque and optimal torque. The hydraulic control device is equipped with air

cooling device, Equipped with oil cooler ,Electrical air conditioning ,There is an emergency stop

device on the control panel;

3.Technical parameters

3.1 SLD16-70 Bucking Unit main engine

3.1.1 pipe size range: 2-7/8 "~16"

3.1.2 Max torque: 70Kn.m

3.1.3 rotary speed range: 0-6 r/min;

3.1.4 Maximum supply pressure: 18MPa

3.1.5 Chassis length 4.5m

3.1.6 weight: 17500kgs

3.2 hydraulic power unit (air cooling)

3.2.1 Max working pressure:20MPa

5/63.2.2 Nominal displacement:180 L/min

3.2.3 Tank volume:600L

3.2.4 Oil pump motor power 37KW

3.2.5 Rated operating oil temperature: <65℃

3.2.6 Dimension: 2000×1510×1800mm

3.2.7weight: 2000kgs

3.3 Torque automatic control system

3.3.1 Supply voltage: 380AC

3.3.2 working voltage:220V

3.3.3 Power consumption: 500W Max

3.3.4 Torque meter range: 0-80kN.m

3.3.5 Control range: can be set

3.3.6 Detection accuracy: ≤±2%,

3.3.7 unloading and effusion: 80L/min

3.3.8 Unloading response: 20ms

3.3.9 Environment temperature: -20℃ to +65℃

3.3.10 Environment humidity: 10% to 80% R·H (No condensation)

3.3.11 Volume: L 600mm*W 500mm*H 300mm

3.3.12 weight: 80KGS

3.4. Console

3.4.1 Dimension (LxWxH): 1700×1000×1300mm

3.4.2 weight: 200KGS