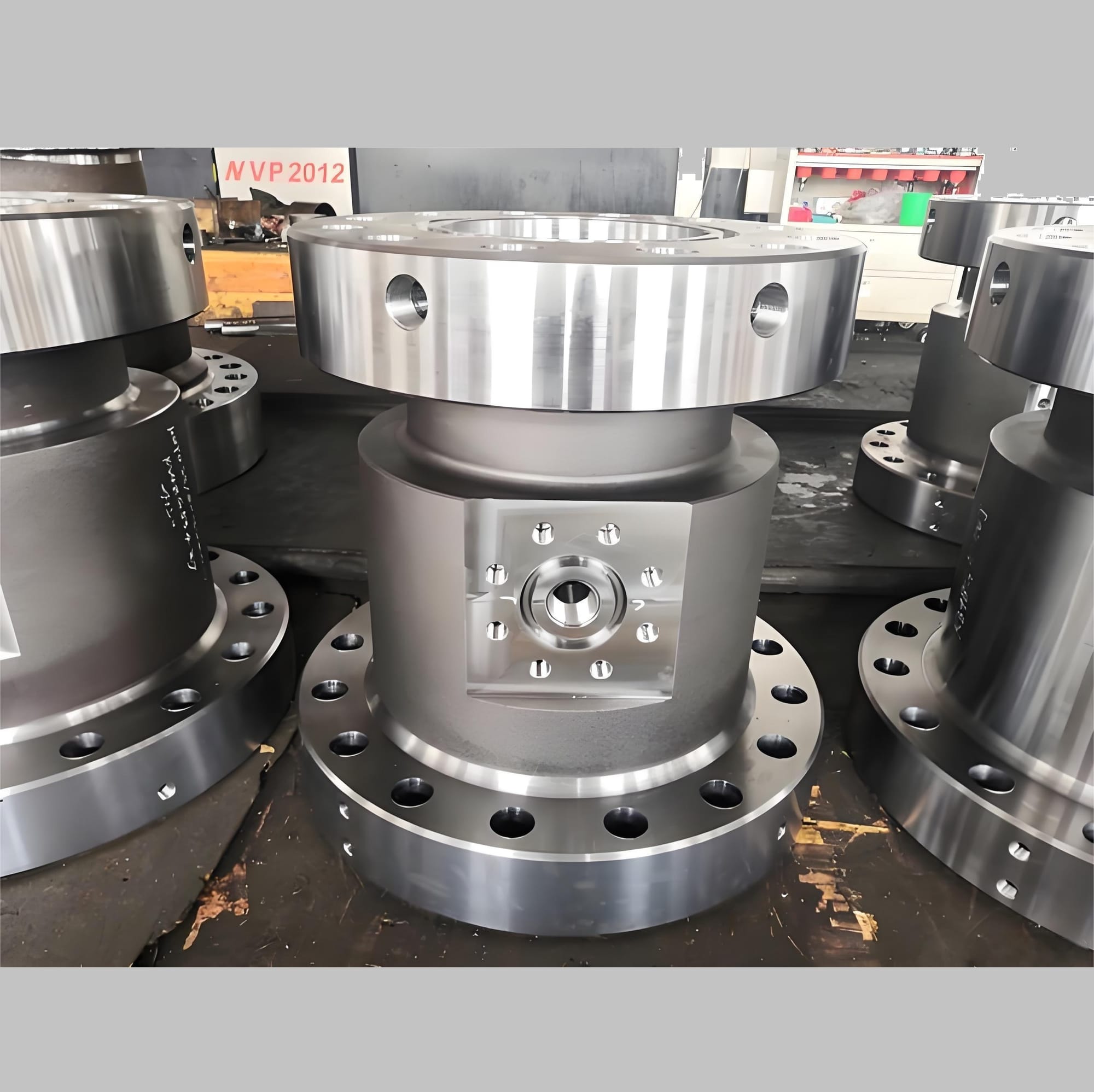

API Standard 9-5/8-inch casing head

The API Standard 9-5/8-inch casing head is a high-quality, durable product essential for oil and gas drilling operations. Designed to provide secure and reliable sealing, it conforms to industry standards to ensure safety and performance under extreme conditions, making it an integral component in the drilling infrastructure.

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

9-5/8-inch casing head

Products Information

----------------------------

The 9-5/8-inch casing head is a crucial equipment used at the wellhead of oil and gas drilling. It is primarily used to secure the wellhead, connect the casing string, and seal the annular space between the pipes, providing a connecting transition for blowout preventers, tubing heads, etc

Basic function and structure:

----------------------------------

This casing head utilizes a slip-type hanger to suspend the casing. For instance, in specifications of 13 3/8×9 5/8×5 1/2, the 13 3/8-inch casing hanger adopts an integral opening and closing reverse slip jaw structure. During installation, the slip jaw is activated to grip the casing tightly by screwing in the bottom slip bolt, forming a reliable connection. Sealing is achieved by injecting sealing grease (approximately 18 MPa) through the "BT" seal ring. The casing head assembly typically includes a spool, gate valve, and related connecting pieces. The diameters of the flange and side ports comply with the API Spec 6A standard.

Main technical parameters: Typical parameters include:

working pressure up to 35MPa (5000psi),

vertical drift diameter of 230mm,

connection type of API 6A flange (such as 13 3/8″-5000psi BX160),

working temperature range of -29℃~121℃,

material grade of DD forged piece,

suitable for general acidic environments,

product specification level of PSL2

performance level of PR1

Installation and Operational Features:

-----------------------------------------------

During installation, it is necessary to ensure that the end face of the casing is horizontal and the groove is polished. The levelness and height are adjusted by fine-tuning the support tray. The slip bolts are symmetrically tightened to enhance the seal. Compared to welded casing heads, the slip design has advantages such as simple structure, fast installation (completed within 1 hour), no need for welding, less affected by climate, and reusability.

Specification variants and applications:

---------------------------------------------------

Common specifications such as 9-5/8″×7″-35MPa can also be extended to multi-level combinations (such as 13 3/8×9 5/8×5 1/2), suitable for surface casing fixation; some variants can achieve a working pressure of up to 70MPa, but their applicability needs to be verified according to API standards