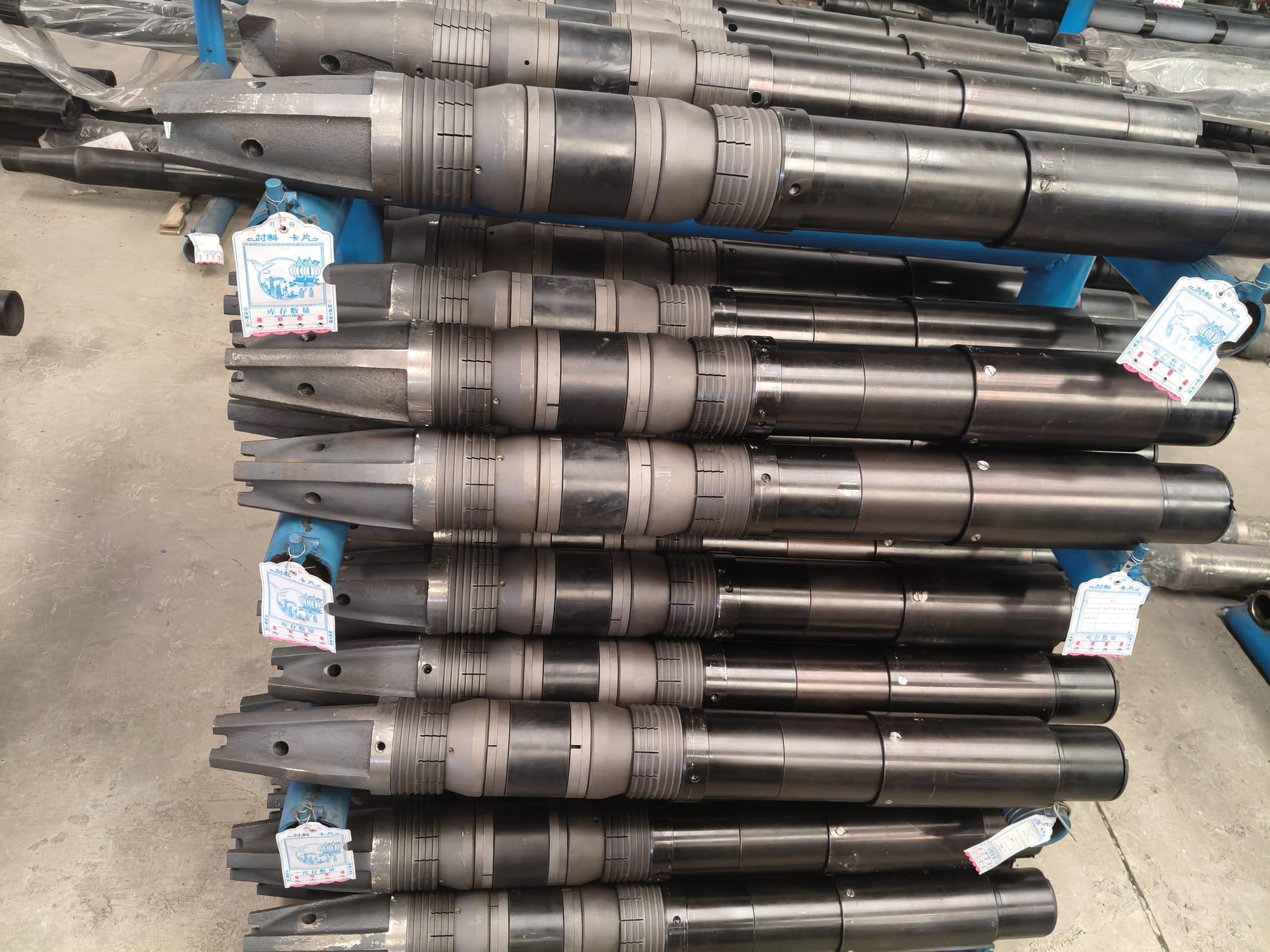

6-5/8" Mechanical cement retainer setting tool

The mechanical cement retainer setting tool is a mechanically operated device used for installing and setting cement retainers in the wellbore. It performs setting, releasing, and retrieving of the cement retainer through mechanical actions such as applying weight, right-hand rotation, and lifting. This tool is widely used in squeeze cementing, zonal isolation, and well repair operations in oil and gas wells.

- Brand: Sunjoy

- SKU: 3

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

Mechanical cement retainer setting tool

Products Information

-------------------------

Products Name: 6-5/8" Mechanical cement retainer setting tool

Size: 6-5/8"

The mechanical setting tool is a device designed for installing cementing packers and drillable bridge plugs.

Due to its built-in latch and sealing assembly, the tool locks into the cementing packer when setting weight is applied and releases when pulled upward or rotated to the right.

Features and Advantages:

Releases upon right-hand rotation combined with upward movement.

Built-in stinger for installing cementing packers.

Locks when setting weight is applied.

Setting is performed by right-hand rotation.

Technical Specifications:

Nominal diameter of production casing: 168.3 mm (6 5/8 in).

Casing weight: 17–32 lb/ft.

Minimum internal diameter of casing: 142.8 mm (5.625 in).

Maximum internal diameter of casing: 154.8 mm (6.094 in).

Outer gauge diameter: 136.5 mm (5.375 in).

Outer diameter (across springs): 213.4 mm (8.401 in).

Total length: 1581.6 mm (62.27 in).

Seal bore diameter: 2 in (50.8 mm).

Stinger internal diameter: 1.25 in (31.75 mm).

Flow area through stinger: 1.23 in².

Maximum working pressure: 5000 psi (34.5 MPa).

Metal material: Steel 4130–4145.

Elastomer: Nitrile, working temperature up to 250°F (120°C).

Top connection: 2-7/8 in EUE BOX (tubing coupling 73 mm).

The mechanical setting tool shall be manufactured in accordance with the requirements of GOST ISO 14310-2014.

The mechanical setting tool shall be manufactured according to the drawing in Appendix No. 1 to this technical specification.