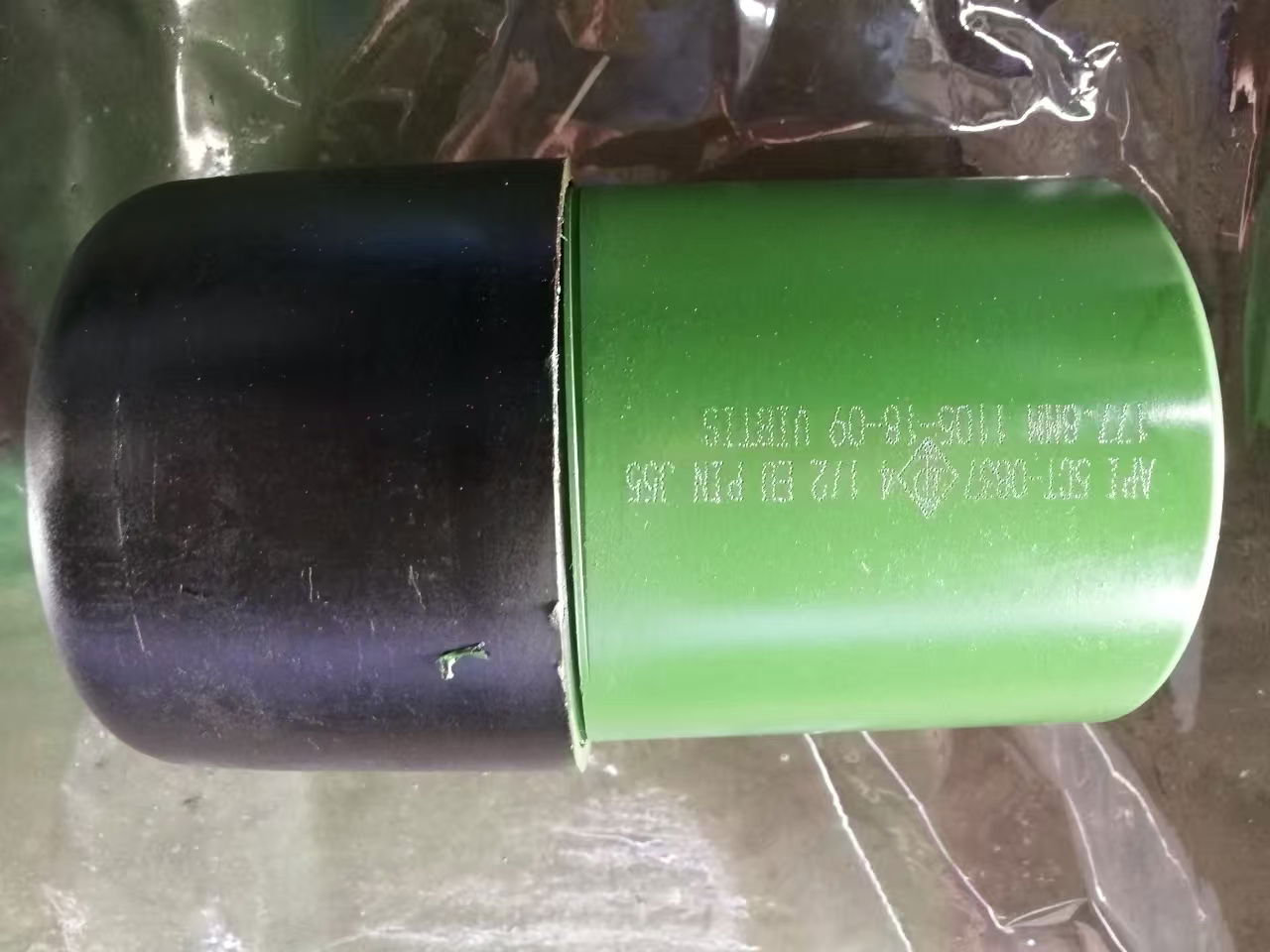

Blind Plug 3-1/2in EUE 8RD BOX N80 Grade

The Blind Plug 3-1/2in EUE 8RD BOX is a durable and reliable component designed for industrial applications. Its dimensions and threading specifications ensure compatibility with standard equipment, providing a secure seal to prevent leakage and ensure operational efficiency. Crafted from high-quality materials, it is suitable for demanding work environments. Whether for temporary or permanent use, this plug offers excellent performance and longevity, making it a valuable addition to your toolkit.

- Brand: Sunjoy

- SKU: 652

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

Blind Plug

(BLIND PLUG, CONNECTION SIZE 3-1/2 in, THREAD TYPE EUE 8RD BOX, MATERIAL CARBON STEEL, STANDARD AND GRADE API 5CT N80.)

A blind plug for pipe is a type of downhole tool used in oil and gas drilling or well completion operations. Its core function is to seal the inner channel of a pipe (such as casing or tubing) temporarily or permanently to isolate specific well sections or prevent fluid flow between them.

Key purposes:

- Well section isolation: When performing operations like cementing, testing, or workover in a specific well section, the blind plug seals the pipe below the target area to avoid fluid interference from other sections.

- Pressure control: It blocks the pipe to maintain pressure in the upper wellbore, ensuring safe execution of operations such as perforation or logging.

- Temporary plugging: Some blind plugs are designed to be removable (e.g., via mechanical activation or pressure), allowing the pipe channel to be reopened after the operation is completed.

In simple terms, it acts like a "downhole stopper" for pipes, controlling fluid flow and isolating well sections as needed.

A blind plug for pipe (downhole) works by creating a secure seal inside the pipe (e.g., casing, tubing) to block fluid flow or isolate well sections. Its operation depends on the design, but the core principle involves expanding or engaging components to press against the pipe inner wall, forming a tight seal. Here’s a general breakdown of how common types work:

1. Mechanical Blind Plugs (Most Common)

These rely on mechanical force (e.g., via a drill string or tool string) to activate the sealing mechanism.

- Key Components:

- Mandrel: The central shaft that transmits force.

- Sealing Elements: Rubber or elastomeric cups/elements that expand to seal.

- Anchoring Mechanism: Slips or buttons that grip the pipe wall to prevent movement.

- Working Process:

1. Run-in: The blind plug is lowered into the pipe via a tool string to the target depth.

2. Set (Activation): Once in position, force is applied (e.g., by lifting or rotating the tool string). This pushes the mandrel upward, compressing the sealing elements.

3. Sealing & Anchoring: The compressed elements expand radially, pressing tightly against the pipe inner wall to seal the flow. Simultaneously, anchoring slips (metal teeth) are forced outward to grip the pipe, holding the plug in place.

4. Release (If Removable): To remove, reverse the activation force (e.g., rotate in the opposite direction). This retracts the slips and allows the sealing elements to decompress, freeing the plug for retrieval.

2. Hydraulic Blind Plugs

These use wellbore fluid pressure to activate the seal, suitable for deeper or high-pressure wells.

- Key Components:

- Pressure-actuated Piston: Responds to fluid pressure.

- Sealing Elements: Similar to mechanical plugs but expanded by hydraulic force.

- Working Process:

1. Run-in: Lowered to depth with the sealing elements in a collapsed state.

2. Pressure Activation: Fluid is pumped into the tool string, increasing pressure inside the plug. This pushes the piston, compressing the sealing elements to expand and seal the pipe.

3. Anchoring: Hydraulic force also engages slips to anchor the plug.

4. Release: Some designs use a "shear pin" that breaks under high pressure, allowing the plug to retract and be retrieved.

3. Permanent Blind Plugs

For long-term isolation (e.g., abandoning a well section), permanent plugs are designed to stay in place. They may use:

- Cement: After setting, cement is pumped around the plug to固化 it in the pipe.

- Non-retrievable Mechanisms: No release feature—once set, they cannot be removed.

In summary, regardless of the type, a blind plug’s core function is to use mechanical or hydraulic force to expand sealing elements against the pipe wall, creating a leak-tight barrier to control fluid flow or isolate well sections.