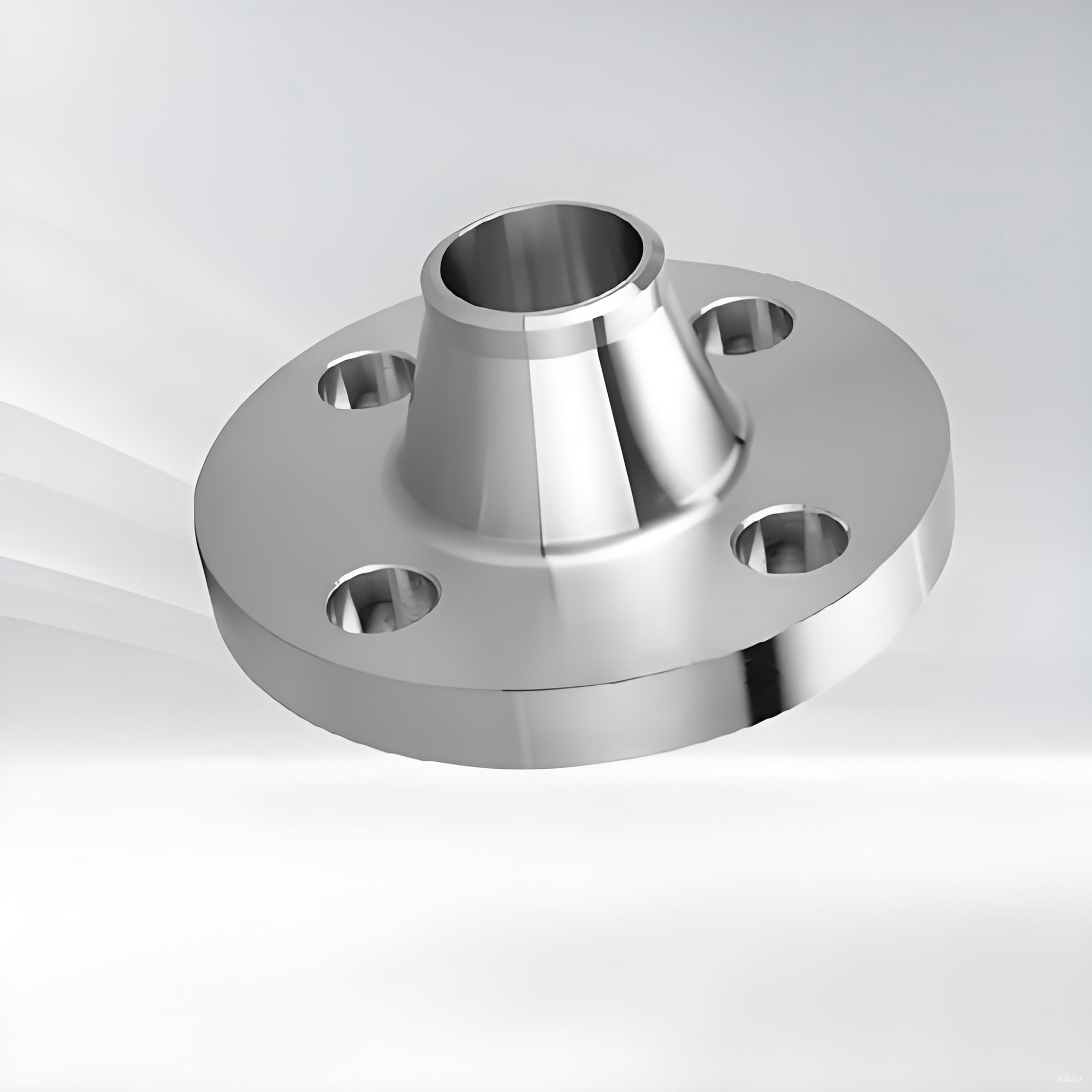

10" Flange,ANSI 300,RF125-250,SCH 20 ASA182-F9

The "10-Inch Flange" is a high-quality pipeline fitting designed to meet ANSI 300 standards for robust and reliable performance. With its raised face of 125-250 specifications and constructed from schedule 20 ASA182-F9 material, it offers exceptional durability and precision for various industrial applications. This flange ensures secure connections and long-lasting utility in demanding conditions.

- Brand: Sunjoy

- SKU: 158

- Shipping:

- Return Policy: <div class="return-policy"> <h2>No-Risk Return Policy</h2> <p>Not 100% satisfied? We make returns easy.</p> <div class="highlight-box"> <h3>🔄 30-Day Returns</h3> <p>Return any item in original condition within 30 days for a full refund.</p> </div> <h3>📦 How to Return:</h3> <ol> <li><strong>Contact us</strong> at returns@yourstore.com with your order number</li> <li><strong>Get approval</strong> + return shipping label (if applicable)</li> <li><strong>Ship back</strong> via prepaid method</li> </ol> <h3>❗ Important Notes:</h3> <ul> <li>Refunds exclude original shipping fees</li> <li>Customs duties on international returns are non-refundable</li> <li>Final sale items marked "Non-returnable" are excluded</li> </ul> <p>🔔 <em>Need help? Chat live with our support team → [右下角聊天图标]</em></p> </div>

Learn More

10" Flange,ANSI 300,RF125-250,SCH 20 ASA182-F9

Detailed Explanation of 10" Flange, ANSI 300, RF125–250, SCH 20, A182-F9

1. General Description

A 10-inch flange is a connecting component used to join pipes, valves, pumps, and other equipment in a piping system. It provides a reliable way to assemble and disassemble sections for inspection, maintenance, or repair.

2. Specification Breakdown

| Item | Description |

|---|---|

| Size: 10" | The nominal pipe size is 10 inches (approximately 273 mm outside diameter). |

| Pressure Rating: ANSI 300 | This refers to Class 300 as per ASME/ANSI B16.5 standard. It defines the maximum allowable working pressure and temperature. Class 300 flanges can handle around 740 psi (51 bar) at 100°F (38°C). |

| Facing Type: RF125–250 | RF means Raised Face, the most common sealing surface for industrial flanges. The 125–250 indicates the surface roughness of the gasket contact area, measured in microinches AARH (Arithmetic Average Roughness Height). This finish ensures a good seal when compressed with a gasket. |

| Schedule: SCH 20 | Refers to the wall thickness of the pipe connected to the flange. Schedule 20 means a relatively thin wall pipe compared to SCH 40 or SCH 80. It helps determine the inner diameter and weight of the piping system. |

| Material: ASTM A182 F9 | This is a forged alloy steel, containing approximately 9% Chromium and 1% Molybdenum (9Cr–1Mo). The material has excellent high-temperature and corrosion resistance, making it suitable for power plants, refineries, and petrochemical applications. |

3. Typical Applications

Steam and high-temperature service lines

Refinery and petrochemical piping systems

Power generation and boiler piping

High-pressure or corrosive environments

4. Common Flange Types Available in This Specification

Welding Neck Flange (WN) – best for high-pressure/high-temperature systems

Slip-On Flange (SO) – easier to install, suitable for lower pressure

Blind Flange (BL) – used to close the end of a pipe

Socket Weld or Threaded Flanges – for smaller diameter or special connections

5. Standards and Compatibility

This flange conforms to the following standards:

ASME B16.5 – Pipe Flanges and Flanged Fittings

ASTM A182 – Forged or Rolled Alloy-Steel Pipe Flanges

ASME B16.47 (for larger sizes, if applicable)

MSS-SP44 – Steel Pipeline Flanges

6. Summary

In short, a 10" ANSI 300 RF125–250 SCH 20 A182-F9 flange is a 10-inch, Class 300-rated, raised-face alloy steel flange designed for high-temperature and high-pressure service. It combines mechanical strength, corrosion resistance, and precision sealing for demanding industrial environments.