Tubing and Casing

16/05/2025

API 5CT Tubing 2 7/8" EU P110

OCTG, also known as Oil Country Tubular Goods, is a steel pipe specifically designed for oil and gas extraction, also known as petroleum specific pipes. 1. Core Functions & Structural Differences Casing Structural pipe cemented in wellbores to stabilize formations, isolate pressure zones, and prevent groundwater contamination. Diameters: 4.5"–20", min. yield strength 35,000 psi. Tubing Conduit for transporting hydrocarbons to surface. Features upset ends (EUE) for enhanced connection strength. Resists internal pressure and corrosion. 2. Key Applications Casing Types: Conductor: Supports topsoil (20"-36" OD). Surface: Protects aquifers. Intermediate: Isolates unstable zones. Production: Final barrier in pay zones. Tubing Roles: Production flow, corrosion barrier, and workover operations (e.g., coiled tubing interventions). 3. Standards & Manufacturing API 5CT/ISO 11960 compliance. Grades: H40 to Q125 & 13%CR. Processes: Seamless (high-pressure wells) or ERW (cost-effective). 4. Operational Advantages Casing: Lifetime structural integrity post-cementing. Tubing: Replaceable; compatible with premium gas-tight connections.

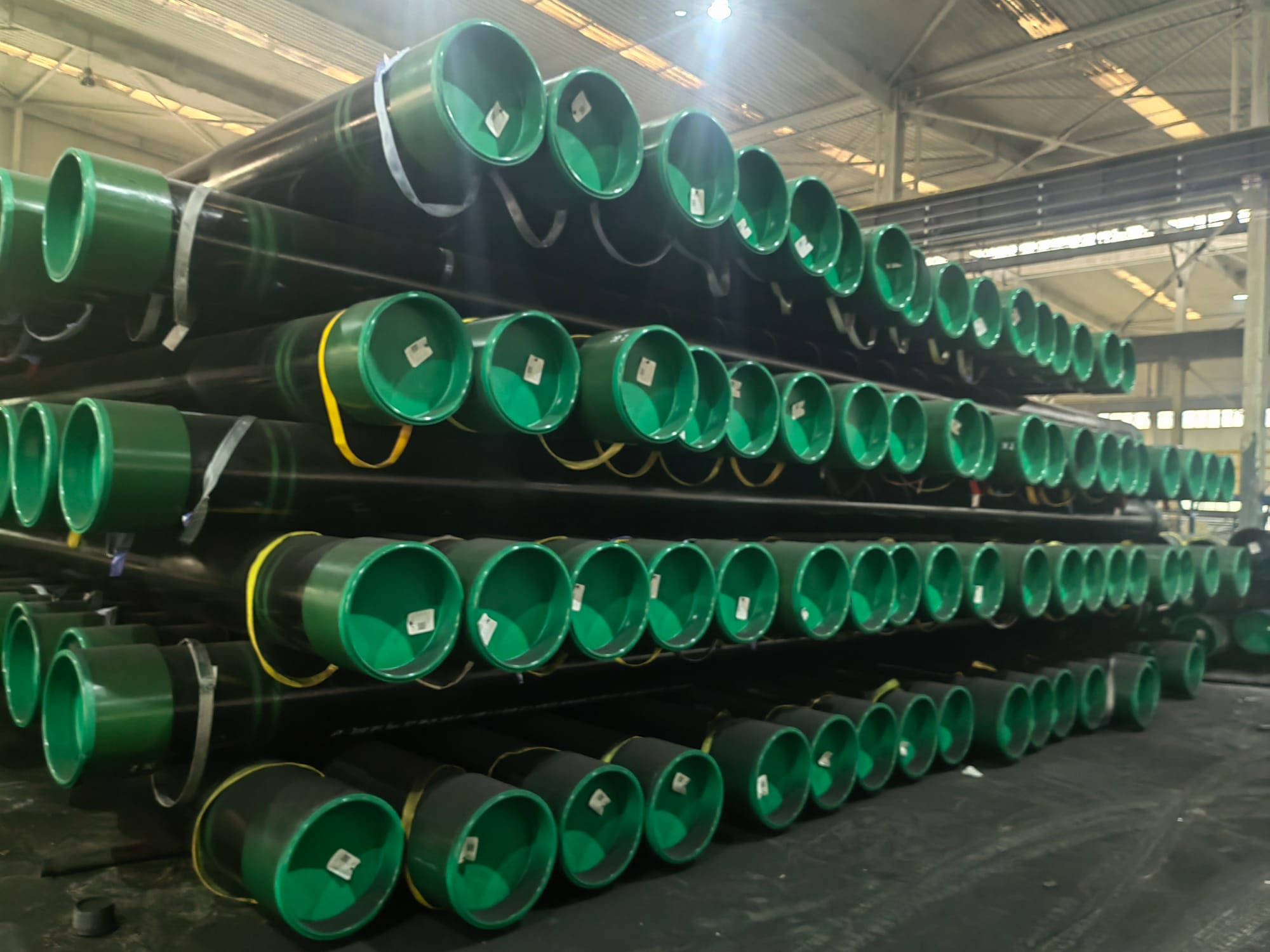

API 5CT Casing Pipe 9-5/8 K55 BC

OCTG, also known as Oil Country Tubular Goods, is a steel pipe specifically designed for oil and gas extraction, also known as petroleum specific pipes. 1. Product Definition The API 5CT 9-5/8" K55 BC Casing is a standard intermediate casing with buttress thread (BC) connection, designed for conventional oil/gas wells. Key features: Size: 244.48 mm OD, wall thickness 8.94–16.13 mm (typical weight 47–53 lb/ft). Grade K55: Yield strength ≥379 MPa, tensile strength ≥655 MPa, superior to J55 in thermal fatigue resistance. BC Thread: High compression/torsional strength, suitable for high-pressure zones and frequent tripping. 2. Key Applications Intermediate Casing: Stabilizes unstable formations (e.g., shale) and isolates pressure zones in wells ≤3,000 m depth (Middle East, Russia). Thermal Wells: Withstands cyclic steam injection (≤300°C) in heavy oil fields (Canada, China). Cost-Effective Solutions: Surface casing for shallow wells and water injection projects where high-grade alloys are unnecessary. 3. Limitations Unsuitable for H₂S-rich environments (upgrade to L80-13Cr) or ultra-deep wells (>4,500 m). 4. Compliance Mandatory tests: Hydrostatic (≥3,000 psi), drifting, NDE (UT/ET). Threading must conform to API 5B, with separate certification required from 2025.

API 5CT Casing pipe 18-5/8 L80 BC

OCTG, also known as Oil Country Tubular Goods, is a steel pipe specifically designed for oil and gas extraction, also known as petroleum specific pipes. 1. Product Definition The API 5CT 18-5/8" L80 BC Casing is a large-diameter structural pipe designed for deep wells and corrosive environments. Key features: OD: 473.08 mm, WT: 10.36–16.88 mm (e.g., 53.5 lb/ft: 13.84 mm). Grade L80: Yield strength 552–655 MPa, with subtypes: L80-1 (general use), L80-13Cr (H₂S/CO₂ resistance, hardness ≤22 HRC per NACE MR0175). BC Connection: Buttress thread excels in compression/torsion resistance, ideal for high-pressure zones. 2. Critical Applications Deep Wells: Intermediate casing for unstable formations (e.g., shale collapse prevention in 4,500m wells). Sour Fields: L80-13Cr resists H₂S-induced cracking (3× lifespan vs. carbon steel in Changqing Oilfield). Offshore Platforms: Surface casing in seawater isolation (e.g., South China Sea projects). Thermal Wells: Withstands cyclic steam injection ≤300°C (Canadian oil sands). 3. Compliance & QA API 5CT-2024: Mandates SSC testing and impact toughness for PSL-2/3. Certification: API Monogram + NACE TM0177 report for L80-13Cr.