YGSY-89 HYDRAULIC PRESS

🔗🔗📍Automatic hydraulic testing machine for oil pipe thread sealing.pdf

1. Overview

The YGSY-89 is a high-performance hydraulic press designed for metal forming, composite material pressing, and laboratory testing. Featuring a modular structure, it offers high precision, stability, and versatility, making it suitable for R&D, industrial production, and quality inspection applications.

2. Key Features

Max Pressure: 50-500T (customizable)

Control System: Servo-hydraulic + PLC automation

Precision: ±0.5% FS (load measurement)

Stroke Length: 100-1000mm (adjustable)

Working Table Size: 600×600mm to 2000×2000mm (options available)

Speed Range: 1-100mm/s (programmable)

Operation Modes: Manual / Semi-auto / Full-auto

3. Structural Components

Frame: Reinforced steel construction with anti-vibration design

Hydraulic Cylinder: Precision-ground, chrome-plated rod for smooth operation

Pressure Gauge: Digital display with peak hold function

Safety Features: Emergency stop, dual-hand operation, light curtains

4. Applications

Metalworking: Stamping, forging, deep drawing

Composite Materials: CFRP/GFRP molding

Laboratory: Material strength testing, sample preparation

Industrial Production: Battery electrode pressing, rubber molding

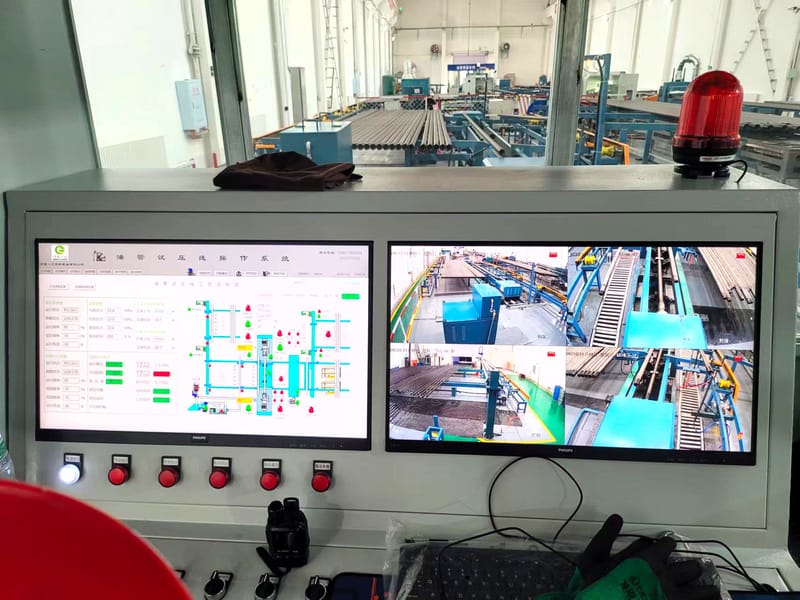

5. Control System

Programmable Logic Controller (PLC): Touchscreen HMI with preset recipes

Data Recording: Real-time pressure/displacement monitoring with USB export

Closed-loop Control: PID algorithm for consistent pressure maintenance

6. Customization Options

Heated plattens (up to 300°C)

Vacuum chamber integration

Multi-stage pressure profiles

ISO/CE certification compliance

7. Maintenance

Regular hydraulic oil checks (ISO VG 46 recommended)

Monthly seal inspections

Annual system calibration