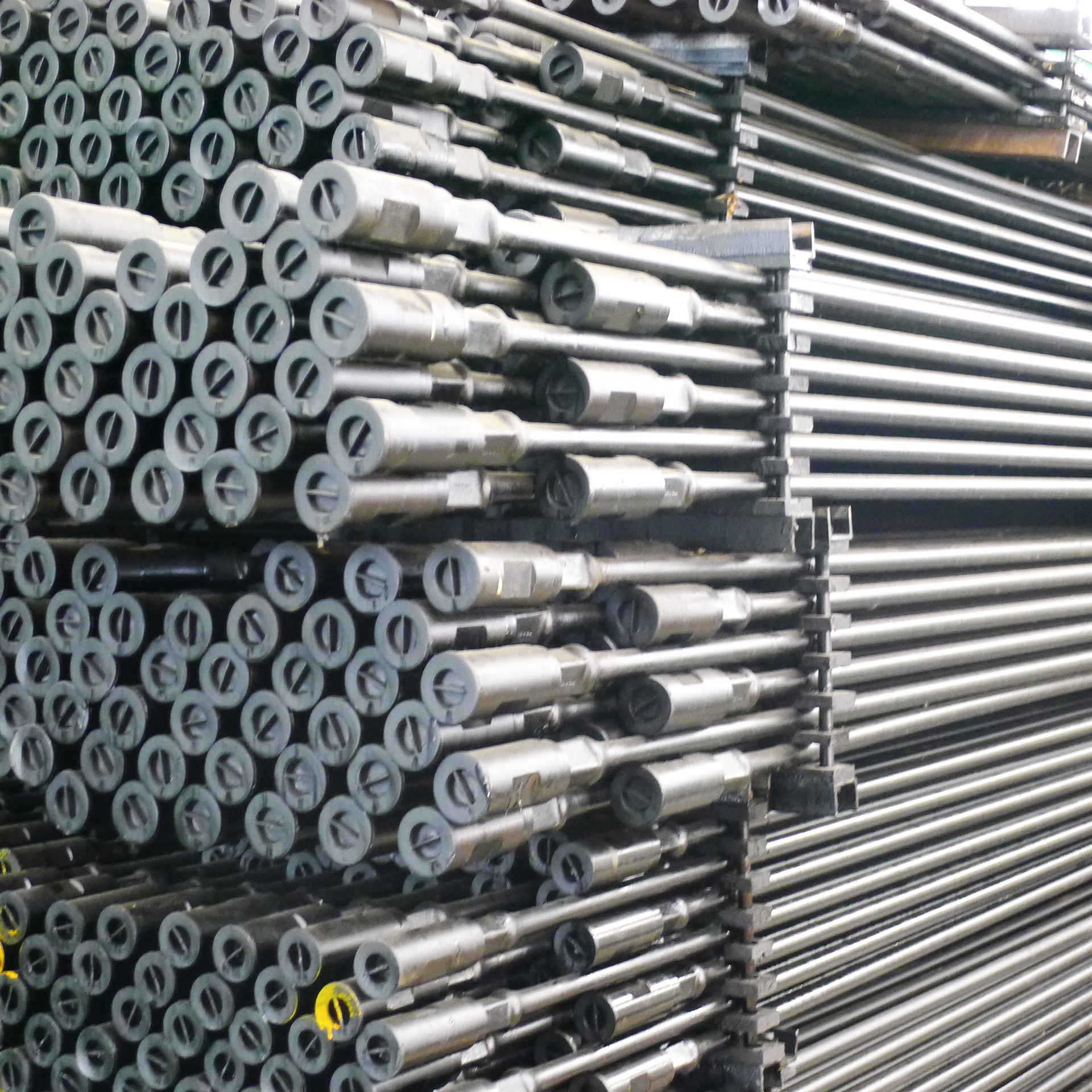

API 11B Sucker rod

18/05/2025

Common sucker rod Grade D or K

In oilfield operations, pump rods (commonly called sucker rods) are critical components for transferring mechanical motion from the surface pumping unit to the downhole pump. Material: High-strength carbon steel. Design: Solid cylindrical rods with threaded ends and couplings. Grades: Classified by API standards (e.g., Grade C, Grade D, Grade K) based on tensile strength and corrosion resistance. Application: Most common type for standard vertical wells.

Polished Rod

What is Polished rods: they are manufactured to meet API Spec 11B (Sucker Rods) for dimensions, materials, and performance. Made of high-strength steel with a hardened, polished surface to reduce friction and wear. Often chrome-plated or coated for corrosion resistance. The polished rod is the topmost segment of the sucker rod string that passes through the wellhead stuffing box. It is a smooth, polished cylindrical rod designed to: 1. Transmit reciprocating motion from the surface pumping unit to the downhole pump. 2. Maintain a dynamic seal at the wellhead to prevent fluid leakage.