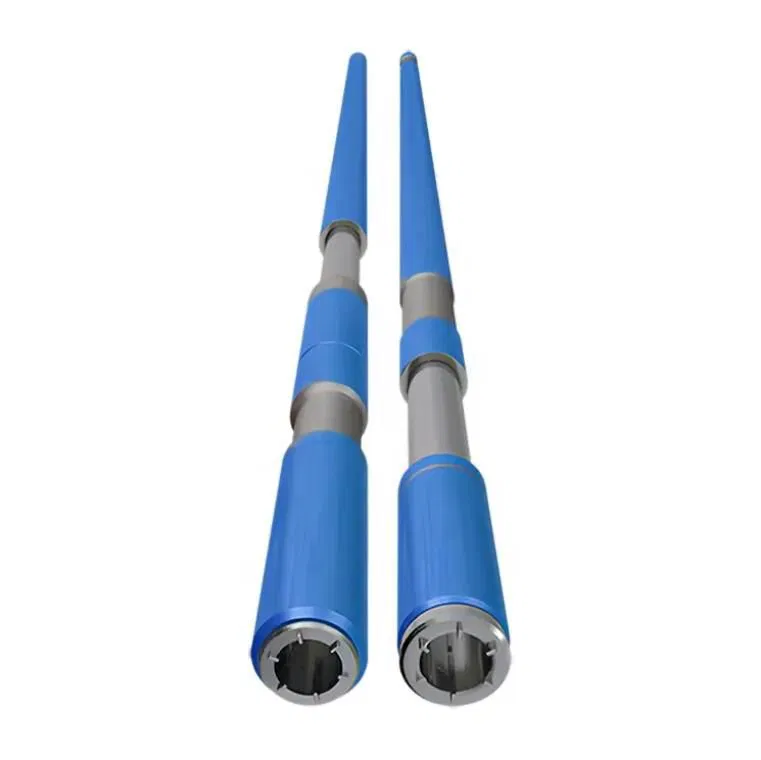

Drilling jar

1. Definition & Purpose

A Drilling Jar is a mechanical or hydraulic tool installed in the drill string to deliver high-impact forces (upward or downward) to free stuck pipe or resolve downhole obstructions. It acts as an "emergency release" mechanism during drilling, workover, or fishing operations.

2. Key Features & Advantages

| Feature | Benefit |

|---|---|

| Dual-Action (Up/Down) | Can jar upward (tension) or downward (compression). |

| Adjustable Force | Hydraulic models allow force calibration based on well conditions. |

| High Reliability | Works in extreme temps (up to 350°F/175°C) and pressures (20,000+ psi). |

| Minimal Fluid Interference | Operates independently of mud flow/pump pressure. |

3. Types of Drilling Jars

| Type | Mechanism | Best For |

|---|---|---|

| Mechanical Jar | Spring-loaded or friction-based release. | Shallow/moderate-depth wells. |

| Hydraulic Jar | Fluid-damped delayed action for higher force. | Deep/HPHT wells. |

| Accelerator Jar | Boosts impact force (paired with main jar). | Heavy stuck pipe scenarios. |

4. Technical Specifications

Sizes: 2⅞" to 9½" OD (matches drill string/BHA components).

Force Range: 50,000–500,000 lbf (hydraulic jars exceed mechanical).

Standards: API 7G (Dynamic Testing) / API 7K (Design).

Materials: High-strength alloy steel with wear-resistant coatings.

5. Applications

Stuck Pipe Recovery: Frees differentially stuck or key-seated pipe.

Fishing Operations: Dislodges stuck tools or debris.

Preventive Placement: Run in high-risk wells (e.g., directional, geologically unstable).