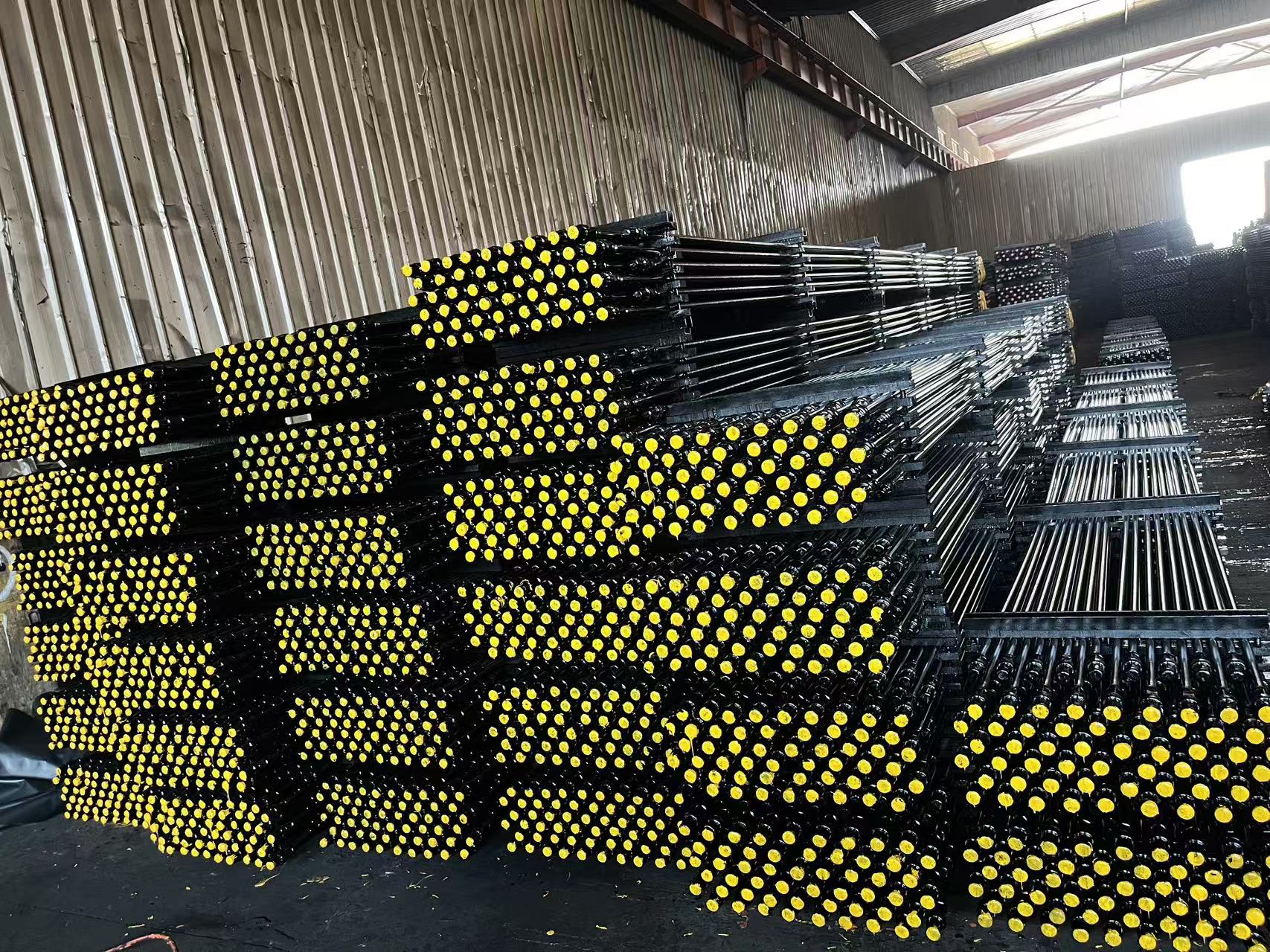

Tige de succion

16/05/2025

Tige de succion

La tige de pompage, composant central des puits de pompage, forme un train de tiges grâce à des accouplements. Son extrémité supérieure est reliée à l'unité de pompage ou au moteur de la pompe à vis, tandis que son extrémité inférieure est fixée au piston de la pompe de fond, assurant principalement la transmission de puissance. Fabriquée principalement en acier allié 30CrMoA, elle est conforme aux normes API 11B et SY/T 5029-2013. Les performances mécaniques sont classées en six catégories : C, D, K, KD, HL et HY. Dans des conditions d'exploitation extrêmes, le train de tiges subit des charges alternées et des milieux corrosifs, ce qui le rend vulnérable aux fractures par fatigue. Environ 90 % des puits pompés par tige dans le monde utilisent des tiges de pompage conventionnelles en acier, dont le diamètre varie de 16 mm à 28,58 mm (1-1/8 po) et la longueur standard de 7,62 m à 9,14 m (25 à 30 pi).