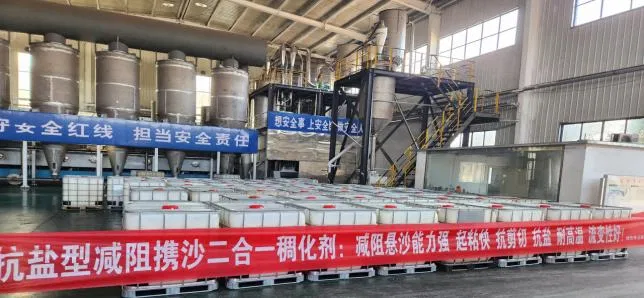

Drilling Fluid Thickener – CH100 Salt-Resistant Friction Reduction and Proppant-Carrying Dual-Function Emulsion

The CH100 Salt-Resistant Friction Reduction and Proppant-Carrying Dual-Function Fracturing Emulsion is an additive designed for high-temperature and high-salinity environments.

- Envío:

Saber más

Drilling Fluid Thickener – CH100 Salt-Resistant Friction Reduction and Proppant-Carrying Dual-Function Emulsion

The CH100 Salt-Resistant Friction Reduction and Proppant-Carrying Dual-Function Fracturing Emulsion is an additive designed for high-temperature and high-salinity environments. Its core features and functions are as follows:

The CH100 Salt-Resistant Friction Reduction and Proppant-Carrying Dual-Function Fracturing Emulsion is an additive designed for high-temperature and high-salinity environments. Its core features and functions are as follows:

Enhanced Salt Resistance

By incorporating salt-insensitive sulfonic acid groups and hydrophobic groups, the product significantly improves viscosity retention (≥70%) in high-salinity brines and wastewater [1]. Compared to traditional carboxylic acid-based thickeners, this design effectively avoids viscosity loss in aqueous solutions caused by salt sensitivity, making it suitable for complex formation environments [1,4].

Integrated Friction Reduction and Proppant Transport

Leveraging the long-chain polymer structure of slickwater friction reducers, the emulsion suppresses lateral flow by altering fluid-wall interactions to reduce friction, while enhancing axial flow via viscoelasticity to meet high-rate pumping requirements [4]. Its viscoelastic properties also enable effective proppant suspension, ensuring fracture propagation and uniform sand distribution [4,8].

Temperature Tolerance and Compatibility

Based on a strongly inhibitive compound brine-based fluid design, the CH100 emulsion maintains stable rheological properties at high temperatures (e.g., 90°C) and exhibits good compatibility with common additives such as corrosion inhibitors and swelling inhibitors [3,4].

Environmental and Cost Advantages

Utilizing non-solid-phase weighting technology and eco-friendly materials, it reduces drilling fluid processing complexity and generates general solid waste, aligning with green development standards [3]. The emulsion form facilitates on-site mixing, lowering transportation and storage costs while improving operational efficiency [7,8].

Applications

Primarily used in unconventional reservoir development (e.g., shale oil/gas), it is ideal for fracturing operations under high-temperature, high-salinity, and complex downhole conditions. This system can replace traditional emulsion fracturing fluids to achieve cost reduction and efficiency enhancement [1,4].

Main Components

CH100 Salt-Resistant Friction Reduction and Proppant-Carrying Dual-Function Fracturing Emulsion

The core components of CH100 are designed for high-temperature, high-salinity, and complex operational conditions. Key functional components include:

1. Backbone Polymer Groups

Acrylamide Copolymers: Serve as the foundational thickener skeleton, providing thickening and proppant-carrying capabilities via long-chain polymer structures [4,8].

Sulfonic Acid Groups (e.g., AMPS): Replace traditional carboxylic acid groups to enhance salt resistance and prevent viscosity loss in high-salinity environments [1,3].

Hydrophobic Monomers: Improve temperature resistance and shear stability through hydrophobic associations, adapting to high-temperature formations [1,3].

2. Functional Additives

Salt-Resistant Monomers: Specific monomers (e.g., fluorinated acrylates or tetrafluoroethylene) are introduced via copolymerization to further strengthen salt tolerance [3,4].

Mineral Oil Emulsion Carrier: Acts as a dispersion medium for the emulsion form, ensuring uniform polymer distribution and facilitating on-site mixing [3,8].

3. Auxiliary Components

Emulsifiers and Stabilizers: Maintain emulsion stability and prevent phase separation or sedimentation (e.g., mineral oil-based thickeners and anti-settling agents) [3,7].

Eco-Friendly Materials: Incorporate biodegradable or low-toxicity raw materials (e.g., biodegradable polymers) to reduce environmental impact [3,7].

4. Synergistic Enhancement Components

Dynamic Reversible Crosslinking Groups: Some formulations may include borate or silicon-based functional groups to enhance high-temperature rheological performance and enable self-breaking properties via dynamic chemical bonds [3].

Technical Parameters

Item | Technical information | Nos. | |

1 | Appearance | White or off-white emulsion | |

2 | pH | 6.0–8.0 | |

3 | Solid Content (%) | ≥35 | |

4 | Base Viscosity (170 s⁻¹) | ≤600 mPa·s | |

5 | Stability | No significant stratification | |

6 | Residue Content (0.1%), mg/L | ≤50 | |

7 | Dissolution Time (s) | ≤40 | |

8 | Apparent viscosity(170s’) Mpa.s | - Tap water, 1% oncentration | ≧80 |

9 | 10% simulated brine,1.5% concentration度 | ≧60 | |

- 0.5% KCl brine, 1% concentration | ≧60 | ||

10 | drag reduction rate(0.1%浓度)% | Tap water | >70 |

11 | 0.5% KCl solution (0.1% concentration) | <65 | |

12 | Friction Reduction Variation Rate | <4 | |